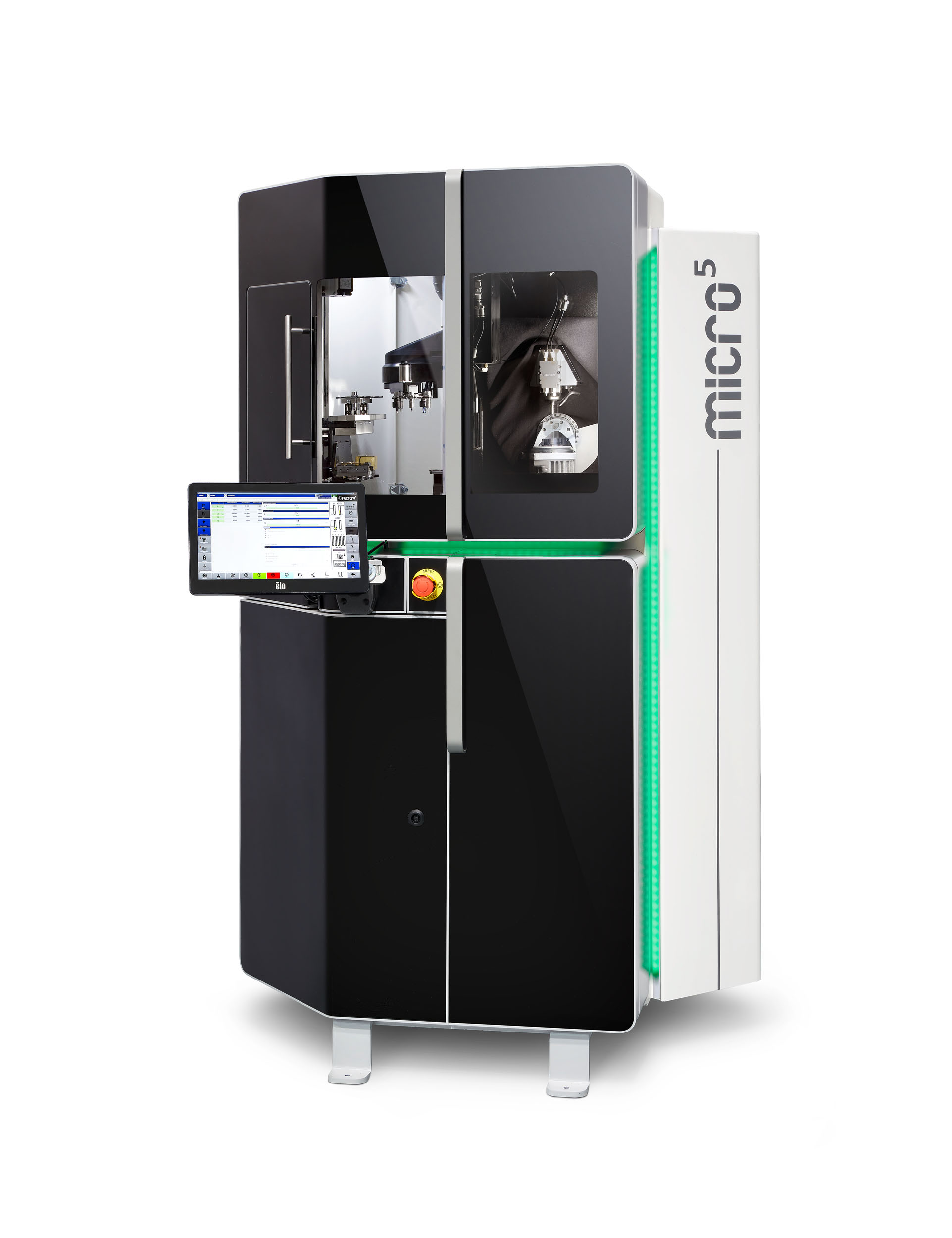

The Micro5 is 5 years old

At SIAMS 2016, HE-Arc presented the prototype of a miniature CNC, called Micro5, that could fit on a desk.

Two years later we introduced a first V0 series of 5 machines industrialized and in operation at the first pioneer users.

By early 2020, we were able to produce a V1 machine every two weeks in lean mode in our 200m2 workshop.

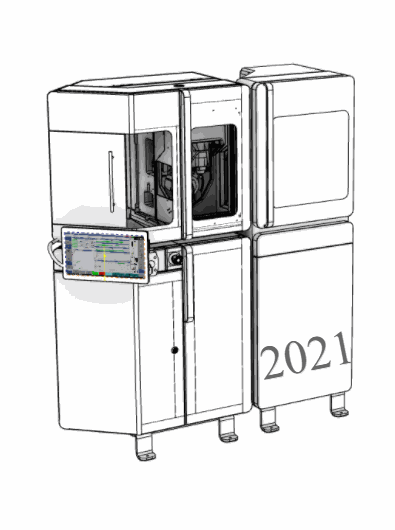

Micro5 V2

Based on user feedback from the first 25 machines, more than 50 new features and improvements are implemented for the 5 years of the first prototype.

3 main lines of action have guided our choices:

Reliability: we have been working intensively on youthful defects and quality at the time of leaving our workshops.

Efficiency: Feedback from the first users indicates gains in terms of machining time reduced by 20 to 40% compared to larger machines. The V2 has a spindle with twice the torque, which allows us to save even more time, about 20%.

Autonomization: We respond to the demand of early adopters who now want to load automatically and achieve volume with our scalable Smartfactory project.

We are convinced that this V2 will be a great success and we hope you will enjoy our work.

V1+

Les nouvelles fonctionnalités notés V1+ sont installables sur les machines V1. Il est possible de demander une offre via notre helpdesk.

Main new features

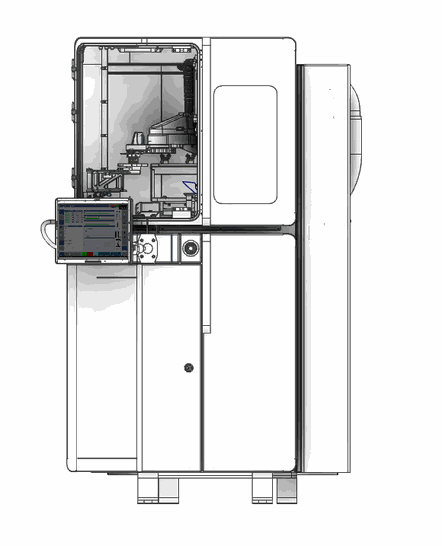

Cowling & Ergonomics

Noise level reduced by 12 db

For a maximum of 49 dbMore...

Sheet metal front panel

Less sensitive to scratches than polycarbonateGlass door for the machining area

Better sound insulationLess sensitive to scratches than polycarbonate

Glass on the right side

New view of the machining area

Pivoting rear hood

Upward opening for better accessibility

Enlarged machine feet

Moving the machine over short distances is now possible with a simple pallet truck.Compact transport

The Micro5 is transportable on a standard Europallet.

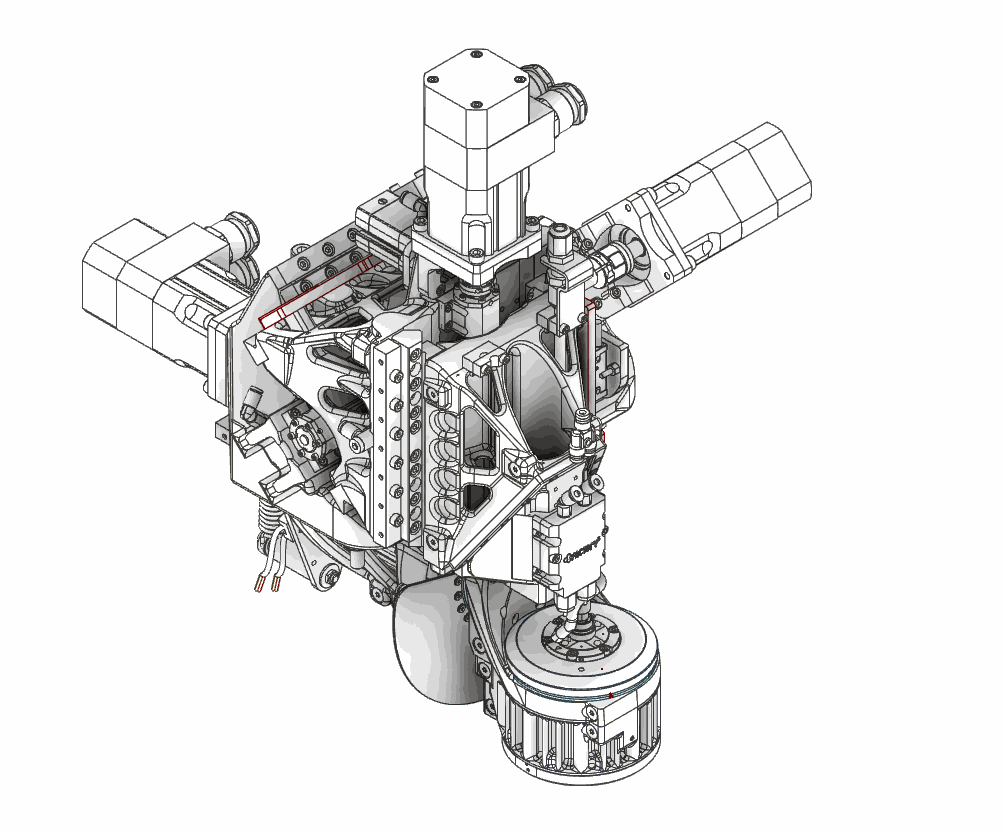

Axis base

C-axis turning

External measuring rules

Better resistance to soilingMechanical pull/push through cradle

Allows additional automatic clamping means

Pressure/vacuum through the cradle

Allows additional automatic clamping means

Cradle in overpressure

Reinforced watertightnessPneumatic Z-axis brake

Performance Improvement

Decrease of the thermal load

B-axis balancing

Performance ImprovementDecrease of the thermal load

Protective canvas

Easy replacementPrevents the cradle from rubbing against the canvas

Centralized lubrication

Improvement of preventive maintenance

Automation

Accélération jusqu’à 2.5 G V1+Paramétrable par l'opérateur (de 0.5G à 2.5G)

Magasin étendu V1+

6 pallets max5 discs of 8 tools = 40 tools

Quick tool change

Cycle in < 5 secondsActivation via interface

Fast palletizing

Quick change cycleActivation via interface

Improved SCARA kinematics

Elimination of superfluous movements during loading functions

Thermal safety

Machine stops if motor temperature is too high (110°C and 150°C)

Filtermist suction system

Power supply and control integrated in the Micro5Now in 230V mono

Activation via interface

Pneumatics

Pneumatic spool valve 64 outlets (instead of 32)

Integrated flow limiters

Cleaner and shorter cable/tube routing

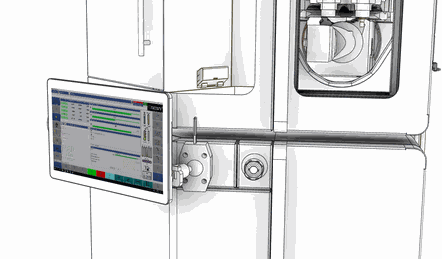

HMI

Gestion des outils frères V1+Selon usure de l’outil

Nouveaux codes de fonctions M V1+

Fréquence des pulsations de la micro-lubrification

Pré-chargement disque

Retour en position initiale du robot

Calibration de la machine en autonomie V1+

Réalisable par l’utilisateur

Géométrie, cinématique, centrage axes

Teaching du Scara V1+

Accessible et réalisable directement par l’utilisateur

Improved interface ergonomics

User-oriented button distributionScope of the signals on a time and XY graph

Upload of usage data

Consumption tracking page

Energy consumption balances (air and electricity)Correction of minor bugs

Cursor freeze, ...Preservation of the sealing blowing if the machine is in error

Integrated interface

HMI in standalone mode

Automatisation

Feed5 compatible

Automatic loadingFirst batch of Feed5 April 2021

Stock5

Large capacity basket storageYear 2022

Micro5 Release Notes - Series 2