Setup

Completed

Transport and handling

Transport and handling (machine packaged)

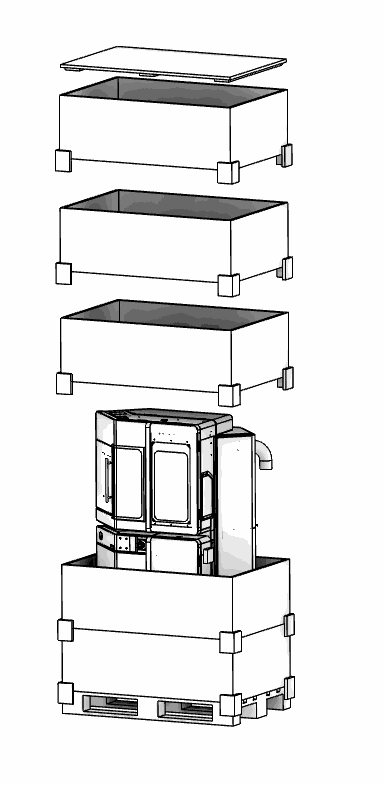

Depending on the variant and options chosen, the Micro5 is transported in 1, 2 or 3 parts. Each part is packaged on a standard Euro pallet (1200 x 800).

Micro5 (height 1960 mm, weight 750 kg approx.)

Next options: Workbench, accessories, tools, etc.

Options: Suction and filtration system, etc...

Transport Kit

The Micro5 must be transported correctly packaged and secured (I).  External options (suction and filtration kit, workbench, loader, etc.) must be disassembled and transported separately beforehand. The transport kit allows the Micro5 to be correctly transported. The kit includes the material for fixing the Micro5, a suitable pallet, the side protections (risers) and the cover.(I). Les options externes (Kit d'aspiration et de filtration, établi, chargeur...) doivent être au préalables démontés et transportés séparément. kit de transport permet de transporter correctement la Micro5. Le kit inclus le matériel de fixation de la Micro5, une palette adaptée, les protections latérales (réhausses) ainsi que le couvercle.

External options (suction and filtration kit, workbench, loader, etc.) must be disassembled and transported separately beforehand. The transport kit allows the Micro5 to be correctly transported. The kit includes the material for fixing the Micro5, a suitable pallet, the side protections (risers) and the cover.(I). Les options externes (Kit d'aspiration et de filtration, établi, chargeur...) doivent être au préalables démontés et transportés séparément. kit de transport permet de transporter correctement la Micro5. Le kit inclus le matériel de fixation de la Micro5, une palette adaptée, les protections latérales (réhausses) ainsi que le couvercle.

Before starting to transport the machine, be sure to properly plan and prepare for the operation by following the points in the manual (II). .

.

Handling operations involve risks;  make sure that each person involved (technician, transporter, forklift operator, etc.) has all the necessary information and is properly trained before transporting the machine.

make sure that each person involved (technician, transporter, forklift operator, etc.) has all the necessary information and is properly trained before transporting the machine.

Once the Micro5 has been correctly packaged and secured to the transport kit, the whole unit must be closed and held in place with straps or belts.

The unit can be moved with a standard forklift or pallet truck.

Stacking of boxes is not permitted, regardless of their position (above and/or below)

Stacking of boxes is not permitted, regardless of their position (above and/or below)

The box must be kept vertical, and must not tilt more than 15°

The box must be kept vertical, and must not tilt more than 15°

The box must be transported and stored in a weatherproof and moisture-free environment

The box must be transported and stored in a weatherproof and moisture-free environment

The box must be handled with care, avoiding shocks and vibrations.

The box must be handled with care, avoiding shocks and vibrations.

The temperature during transport and storage must remain between 0 °C and 55 °C, non-condensing.

The temperature during transport and storage must remain between 0 °C and 55 °C, non-condensing.

Detailed information: V/Specifications & limits § Environmental conditions

"Transport" refers to movement of the machine from one site to another using a means of transport (truck, etc.). A simplified procedure can be used for transporting over short distances, e.g. to another location in the factory (link).

Important (I)

When transporting the Micro5 (both at delivery and during subsequent transport), the transport instructions must be followed and the transport kit used, and the Micro5 must be correctly secured.

Up to SN/002024

The feet of the Micro5 are not designed to withstand transport (shocks, lateral acceleration, etc.). Never transport the Micro5 by simply placing it on its feet!

Important (II)

Before moving the Micro5 and during storage, remove the tool-holder disks, drain the oil and clean the machining booth.

After moving the Micro5 and after storing it, the machine must be left in its place of installation for at least 24 hours at its nominal temperatureV/Spefications & limits), before being commissioned

Danger

Risk of tipping, crushing.

Important information to give to the carrier

The center of gravity of the unit is particularly high.

Do not apply lateral forces: reduce speed when changing direction, accelerate and brake gradually, drive slowly.

When transporting the unit, always secure the packaged machine correctly and fully to the vehicle (strap at 2/3 of the height, not just at the pallet).

During loading, unloading and generally when the unit is not secured to the transport vehicle: keep the load horizontal, do not exceed an angle of 5° (slopes, banks).

Danger

Use of handling equipment

The use of handling equipment involves risks and must be done by trained and authorized personnel. Comply with the rules and regulations in force.

There are no comments for now.