Setup

Completed

Unpacking and setting up

Unpacking and setting up

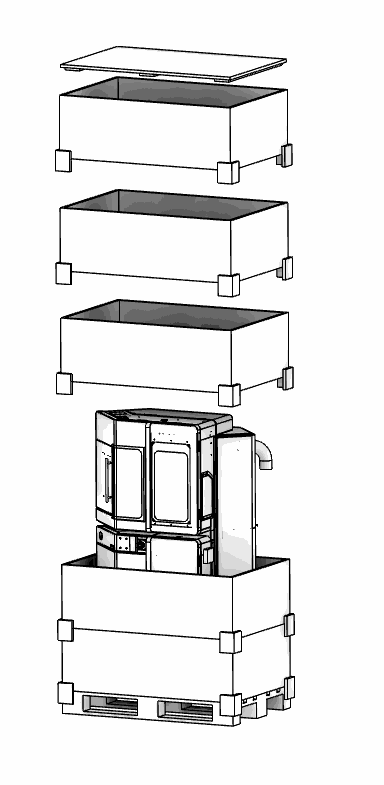

The Micro5 is transported on a standard EURO pallet. A transport kit allows the machine to be secured on the pallet and protected during transport and storage.

Composition of the transport kit

A standard wooden Euro pallet with 4 access points

5 wooden risers

1 cover

2 posts screwed to the edges of the pallet deck along its length

2 metal crosspieces affixed to the wooden posts

4 mounting screws connecting the crosspieces to the Micro5 chassis

The Micro5 must be correctly positioned on the pallet

All feet must be in contact with the base of the pallet. If necessary, insert a board.

Prerequisites

Counterbalanced forklift, minimum capacity: 800 kg

Handling perimeter clear

2 people are needed to unpack and set up

Propcedure

Remove the cover and the risers

Unscrew the metal crosspieces connecting the Micro5 chassis

Raise the machine slightly by unscrewing the adjustable feet

Remove the metal crosspieces and wooden posts

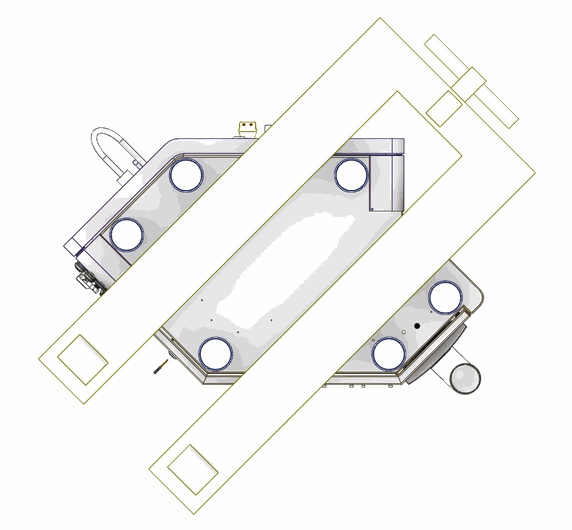

Using a hoist, lift the machine according to the lifting diagram below.

Be careful not to allow the forks of the forklift to collide with the machine's feet..

Be careful not to allow the forks of the forklift to collide with the machine's feet.. Also be aware of the center of gravity, which is particularly high (V/Transport)

Also be aware of the center of gravity, which is particularly high (V/Transport)Place the Micro5 on the ground

A single or short pallet truck can be used to move the Micro5 over short distances indoors. Follow the specific procedure.

Once the Micro5 has been unpacked, it can be moved over short distances using a standard manual pallet truck and without loading onto a pallet. The precautions related to the center of gravity remain valid.

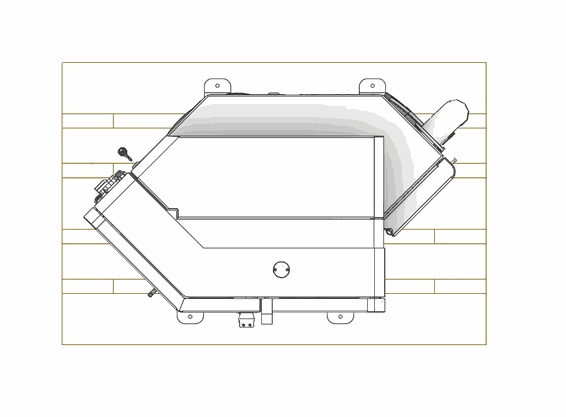

Lifting plan

The machine must be lifted with a pallet truck or forklift (required to remove it from a pallet). The following drawing shows the positioning of the forklift: parallel to the support face of the workbench.

IIt is important to avoid collision with the feet of the machine, so as not to damage them.

Risk of tipping and crushing

The center of gravity of the unit is particularly high..

Keep the load horizontal, do not exceed an angle of 5° (slopes, banks).

Do not apply lateral forces: reduce speed when changing direction, accelerate and brake gradually, drive slowly.

Installation location

Cement base or floor.

It is necessary to check the admissible load of each type of surface, as well as the load distribution. If necessary, consult a specialist.

In order to guarantee perfect operation of the machine, the installation location :

Must be vibration-free

Must not be subject to heating or cooling (e.g. heating bodies, sunlight, drafts, etc.)

Must not contain electrical devices that could cause disturbances (high frequency)

We recommend cement foundations.

IThe machine dynamics may cause the unit to move during operation. This movement is normal and does not affect the quality of the work done, thanks to the machine's design.

The machine must be installed so that all openings and doors remain accessible at all times. A free space must also be provided at the rear of the machine (see dimensional drawings)

Connections

The following connection interfaces must be located near the place where the Micro5 is installed:

Electric: T13 socket (type J)

Pneumatic: flexible hose outer diameter 8 mm

Option: LAN and WAN network (2xRJ45)

Details of the connections are discussed in the relevant section.

There are no comments for now.