Manual

Completed

Limits of use

Features & limitations

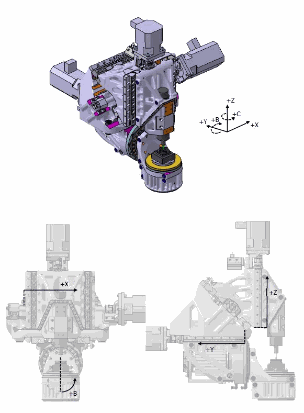

Architecture

Serial architecture Room size* Milling Repeatability Targeted accuracy Moving masses Static rigidity NC part dimensions NC part weight * Max gross dimensions *Details: V/ e-learning article | 4 ou 5 axes 50 x 50 x 50 [mm] UGV ±0.5 [µm] ±1 [µm] ~10 [kg] K = 1.36x10^6 [N/m] 500 x 600 x 500 [mm] 55 [kg] 80x50x56 / Ø80x50 [mm] |

Linear axes

Fast forward speed Acceleration Resolution Maximum error | 30 [m/min] 15 [m/s2 ] 1 [µm] 0.5 [µm] |

X axis Travel (hard/mechanical) Measurement range Peak force | 80 / 81 [mm] 78 [mm] 570 [N] |

Y axis Travel (hard/mechanicaé) Measurement range Peak force | 58/60 [mm] 56 [mm] 570 [N] |

Z axis Travel (hard/mechanical) Measurement range Peak force | 52/56 [mm] 50 [mm] 280 [N] |

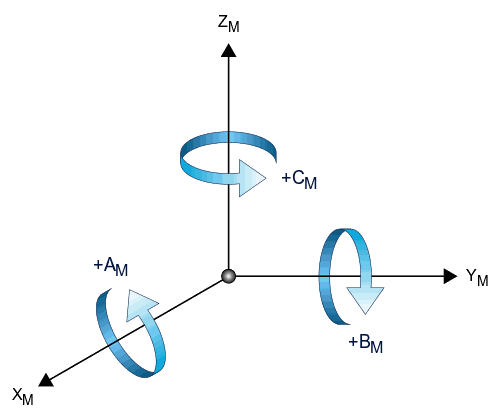

Rotary axis

| B axis Travel (hard/mechanical) Measurement range Resolution Maximum error Peak torque Maximum acceleration. | 125 / 140 [°] 110 [°] 0.002 [°] 0.005 [°] 7.3-8.9 [Nm] 800 - 1000 [rad/s2 ] |

| C axis Travel (hard/mechanical) Measurement range Resolution Maximum error Peak torque Maximum acceleration | 360+[°] 360+ [°] 0.002 [°] 0.015 [°] 1.25 [Nm] 1000 [rad/s2] |

Spindle Detailed specifications, see articles in the shop

Micro5 V0 & V1 | Machines SN/000202 --> SN/002024 |

Vitesse de rotation maxi Durée de vie du système de serrage Diamètre max outil (mm) Fraisage laiton/alu Fraisage inox/titane Perçage laiton/alu Perçage inox/titane | 60'000 t/min 1'000'000 Cycles 3.0 2.0 2.5 1.5 |

Micro5 V2 | Machines from SN/002025 onwards |

Max. speed of rotationi Durée de vie du système de serrage Diamètre max outil (mm) | 28'000 t/min 700'000 Cycles 6 |

| Max. speed of rotationi Durée de vie du système de serrage Diamètre max outil (mm) Fraisage laiton/alu Fraisage inox/titane Perçage laiton/alu Perçage inox/titane | 60'000 t/min 700'000 Cycles 3.0 2.0 2.5 1.5 |

Max. speed of rotationi Durée de vie du système de serrage Diamètre max outil (mm) | 80'000 t/min 700'000 Cycles 3 |

Operation below 20,000 [rpm] is not recommended.

The detection of a spindle stop is not guaranteed.

The detection of a spindle stop is not guaranteed.

La vitesse maximum doit être adaptée au type d'outil utilisé, au diamètre et au type de tasseau.

Mega4S: max 55'000 rpm.

Mega6S: max 40'000 rpm.

Schaublin-FRE6: max 55'000 rpm.

Lubrication

Microlubrication

| Tank | 0.8 [liters] |

| Nominal power consumption (factory setting) Adjustment range | 1.86 [ml/h] 0.372 ... 83.7[ml/h] |

| Average annualized consumption | ~3 [Liters/an] |

| Compressed air consumption | 0 ... 200 [L/min] |

Whole oil

| Tank | 14 [liters] |

| Nominal flow rate | 0 ... 6 [liters/min] |

| Compressed air consumption | 0 ... 200 [L/min] |

Dimensional drawings.

Size and weight for transport: Transport and handling

According to IEC 61672-1

| Micro5 - Série 00 Jusqu'à et y compris SN/000204 Sound levels | 53.5 [dB(A)] @ 45'000 [min-1] 62.7 [dB(A)] @ 60'000 [min-1] |

| Micro5 - Série 01 Compris entre SN/000244 et SN/002024 Noise level | 50.7 [dB(A)] @ 45'000 [min-1] 60.1 [dB(A)] @ 60'000 [min-1] |

| Micro5 - Serie 02 From and including SN/0002025 Noise level | 49.2 [dB(A)] @ 45'000 [min-1] 51.3 [dB(A)] @ 60'000 [min-1] |

Environmental conditions

| Température ambiante nominale (recommended in operation. Details, V/external conditions) | +20°C ±2°C |

| Ambient temperature range (in limited operation. Details, V/external conditions) | Minimum +5°C Maximum +35°C |

| Ambient temperature range Storage only. Leave the machine at room temperature for at least 24 hours before switching it on. | Minimum 0°C (sans condensation) Maximum +55°C |

| Air humidity | 5% ... 80% (sans condensation) ~ Classe 3 (ISO 8573.1) |

For details of the on-site commissioning procedure (connections), see the dedicated section of the installation manual"

| Power supply Interface Mains supply type Voltage Frequency Recommended upstream protection Recommended minimum connection cross-section | Fiche T13 (SEV 1011, type 13 - CEI type J, not supplied) Single phase, separate neutral and PE (TN-S / TN-C-S) 230 [Vac] ±5% 50 [Hz] ±2% 10 [A] 3x1.5 [mm2] |

| Alimentation pneumatique Interface Caractéristiques Pression de service Débit maximum requis Qualité minimum (ISO 8573.1-2001) | ⌀8 female push-in fitting [mm] Dry air, oil-free (<1 [mg/m3]) 6 [bar] ~10 [m3/h] Up to SN/002034: Class 3 - 5 From SN/002035: Class 3 |

| Réseau de communication Interfaces Port LAN Port WAN | 2x Ethernet RJ45 physical links Connection to the internal local network Connection to the WAN (Internet) via integrated VPN For details on system requirements, see V/Network ConnectionFront panel connection |

| Front panel connection Power supplies User interface (Only with workbench) | 2x T13 socket, freely usable (max 10 A) e.g. screen, probe 1x HDMI + 1x USB 3.0 (touch interface) 1x ⌀8 female push-in connector [mm] (blower) |

Specifications of the control section

Automatic control unit Model Processor Memory OS Version SCD Version | iPC Beckhoff - CX2040-0125 |

Interface TypeSize Resolution Ports Included | Workbench version Multitouch screen 24'' (60.7cm) 1920 x 1080 pixels 1x VGA, 1x HDMI, 1x DisplayPort, 2x USB 3.0, 2x USB 2.0 Keyboard + Wireless Mouse |

| Type Size Resolution Ports | Standalone version Multi-touch screen 13.30" (33.8cm) 1920 x 1080 pixels N/A |

Software interface Manufacturer Components | Beckhoff TC1200 | TC3 PLC TwinCAT 3 PLC TF5000 | TC3 NC PTP 10 Axes NC PTP for up to 10 axes TF5100 | TC3 NC NC with 3 interpol. axes and 5 additional axes TF5112 | TC3 Kinematic Transformation L3 realization of different kinematic transformations Level 3 TF5200 | TC3 CNC CNC path control software TF5240 | TC3 CNC Transformation transformation functionality (5-axis functionality) TF5250 | TC3 CNC HSC Pack extending the CNC with HSC technology (high-speed cutting) TF5260 | TC3 CNC Spline Interpolation path programming via splines with programmable spline type, Akima-spline, B-spline |

Colors

The following colors are used as standard on the Micro5:

| Intermediate part between the front panels (doors) and the frame, work table. | RAL 9006 "Aluminium blanc" |

| Rear part of the frame and the structure | RAL 9010 "Pure White" |

| Front part and the front of the openings | RAL 9005 "Noir foncé" |

| NC part (X, Y, Z axis castings and B axis cradle) | RAL 7038 "Gris agathe" |

Other colors are available upon request. More time is needed.

Limits related to people

| Transport | Transportation of the machine is the responsibility of the carrier, who must use the components provided for this purpose and follow the instructions supplied. |

| Première mise en fonction ainsi que la formation du personnel | CHIRON Swiss SA technician Under penalty of cancellation of all benefits under the guarantee |

| Start-up and operation | Qualified person |

| Maintenance and repair | Qualified person trained by a CHIRON Swiss SA technician |

| Compliance according to | 2006/42/EC - EC Machinery Directive 2014/30/EU - directive CE “CEM” 2006/95/EC - EC Low Voltage Directive" |

| Harmonized standards used | EN ISO 12100-1, EN 60204-1, EN 294, SN EN 349, SN EN ISO 13850, SN EN 1037, EN 953, EN 1088, ISO 13849-1, EN 574, DIN EN 983, SN EN 12417+A2 |

| Marking |  |

| Electrical part | IEC 61439-1 IEC 60204 |

There are no comments for now.