Maintenance

Completed

Contrôles journaliers

Daily inspections

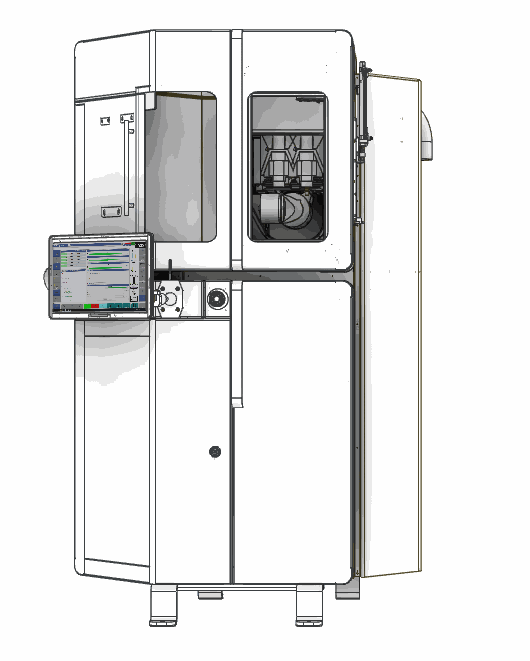

The points to be systematically checked before using the machine concern the safety components and any particularly sensitive elements. These points can and should be addressed directly by the operator. The operator's experience of working with the Micro5 make him/her the most qualified person to accurately and quickly detect any anomalies (noise, behavior, cycle time, etc.). Involving the machine operator in the maintenance process allows anomalies to be quickly identified and the overall quality of the equipment and the parts produced to be improved, while maintaining a high level of user safety.

Daily inspection points do not require any special tools or knowledge.

General condition

Check for leaks at ground level (liquids)

Check for compressed air leakage (machine stopped)

Check the general external condition (shocks, marks, wear and tear, integrity of the transparent panels, doors, condition of the cables, etc.)

Check that all protective covers are in place and that all openings are closed.

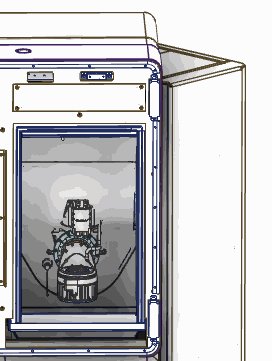

Machining area

Check the integrity of the elastic protective fabric.

.

.Clean the spindle-tool interface (coupling cone). A special tool is available in the shop. [ATC-E15 spindle cone cleaning tool].

Brush and vacuum the fabric and the area under the chip tray.

(I).

(I).Clean the lower guide rail of the partition regularly.

(I).

(I).Visually inspect the probe magazine. If necessary, remove the probe storage cover to check for chip accumulation. Brush and vacuum if necessary.

(I).

(I).

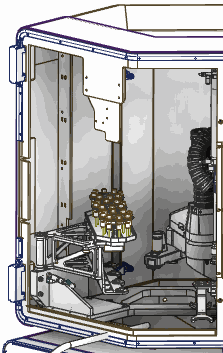

Storage area

Brush and vacuum the loading area

(I).

(I).Clean the tool holder cones with a lint-free cloth. Check that the surface of the cone is clean, dry and in perfect condition.

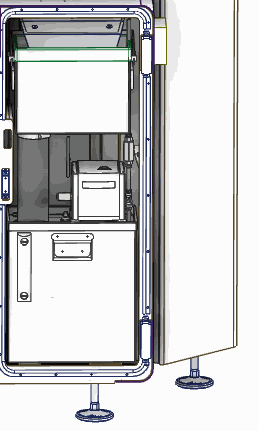

Recovery zone

Check the level of the chip tray, empty and clean if necessary

(I).

(I).Check the level of the filter bag, empty and clean if necessary

(II).

(II).Check the lubricant pump and tank for leaks.

Check the fill level of the lubricant tank. Top up if necessary

(II).

(II).

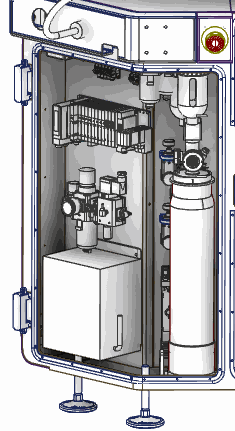

Pneumatic area

Check the lubricant level of the microlubrication system. Top up if necessary

(II).

(II).Check the lubricant pump and tank for leaks.

Check for compressed air leakage.

Important

Regularly check the condition of the protective fabric in the machining area! If it appears damaged, stop using the Micro5 immediately and replace it.

Caution (I)

Never use compressed air to blow out the chips!

Never use solvents to clean the machine surfaces.

Use a vacuum cleaner and a brush to clean the entire machine

Never wipe the exterior surfaces or the transparent panels with a cloth.

Caution (II)

When handling liquid products (oils, lubricants, coolants, etc.), follow your company's safety regulations and the manufacturer's instructions.

Wear appropriate personal protective equipment (gloves, safety glasses).

Immediately clean up or report the presence of fluids on the floor. Wear closed shoes with a non-slip sole.

.

Caution (II)

Risque d'incendie ! Veillez à maintenir le tuyau de connexion propre, sans accumulation de copeaux, en particulier si vous travaillez des matériaux inflammables tels que le titane ou le magnésium.

There are no comments for now.