Maintenance

Completed

Replacing the microlubrication nozzle

The microlubrication nozzle consists of a coated aluminum outer semi-flexible tube and an inner capillary tube. The inner tube contains the oil from the dosing pump. The outer tube contains the compressed air. The air and oil is only mixed at the last moment, at the end of the nozzle.

Prerequisites

The front door of the machining section must remain open.

Open the door BEFORE cutting off the power.

Do not close the door during the procedure (it would then be locked)

The machine must be in maintenance mode (energy supplies off, all axes free).

Rear cover removed

Micro5 series 0 and 1 (up to SN/002024): Removing the rear cover

Micro5 series 2... (from SN/002025): Opening the rear cover

Procedure

Remove the screw holding the nozzle to the triangular insert.

Remove the 3 screws and remove the triangular insert.

Locate the microlubrication hose in the rear part of the machining center

Remove the plastic fasteners.

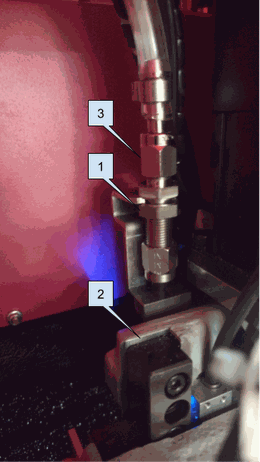

Slightly unscrew the lower nut (1) to release the fitting from the support.

Unscrew the 2 screws (2) on the bracket holding the support assembly on the Z cast iron.

Locate the microlubrication hose in the rear part of the machining center

Remove the plastic fasteners.

Slightly unscrew the lower nut (1) to release the fitting from the support.

Unscrew the 2 screws (2) on the bracket holding the support assembly on the Z cast iron.

Remove the upper connecting nut (3)

Pull the nut up slightly to access the inner tube.

Remove the thin tube from the spline fitting, holding it with pliers so that it does not fall into the guide tube.

Remove the nozzle-fitting assembly from the bottom.

To assemble, proceed in reverse order.

To assemble, proceed in reverse order.

Caution

The machining center can be set in motion automatically.

The forces and high inertia of the moving parts of the machining center pose a risk of serious injury.

Never intervene or remove the guards without having secured the machine.

Keep away from moving parts.

If it is necessary to conserve energy or to carry out movements when the guards are removed (functional tests, diagnostics, etc.), it is necessary to take additional appropriate safety measures (e.g. marking of the danger zone, wearing additional PPE, etc.). A full risk assessment must be conducted with the safety officer.

Cut off the energy supplies and secure the machine

Cut off the energy supplies and secure the machine

Mark and prevent access to the danger zone

Mark and prevent access to the danger zone

There are no comments for now.