Maintenance

Completed

SCARA maintenance

SCARA maintenance

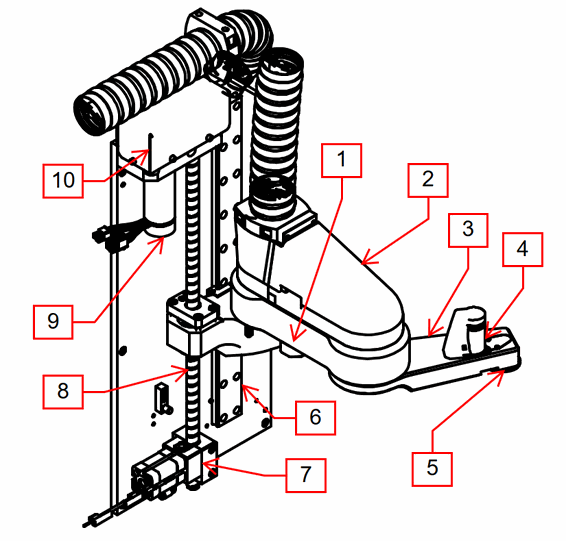

Composants du SCARA components

1st SCARA arm

SCARA cover

SCARA 2nd arm

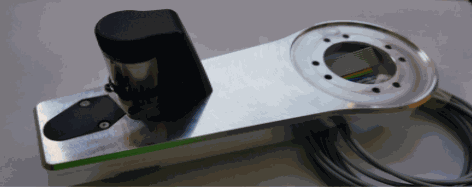

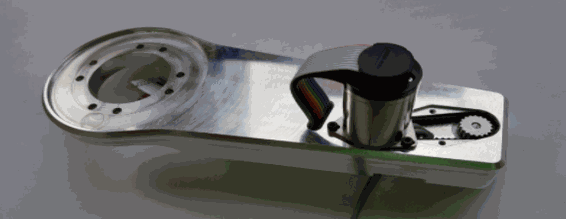

Motor B3 (disk rotation)

Coupling pin

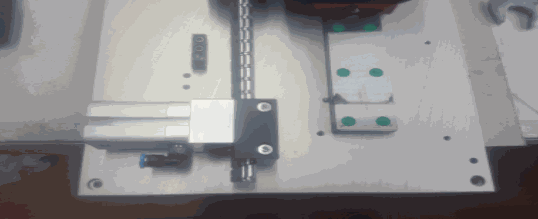

Guide rail

Z axis brake

Ballscrew

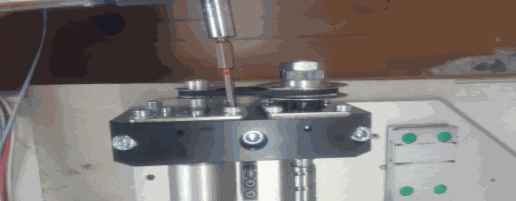

Z axis motor

Z axis motor cover

Prerequisites before intervention

The machine must be in maintenance mode (power off).)

.

.Rear cover removed

SCARA disabled and Z brake open

Caution

The SCARA can start moving automatically..

The forces and high inertia of the SCARA pose a risk of serious injury.

Never intervene or remove the guards without having secured the machine.

If it is necessary to conserve energy or to carry out movements when the guards are removed (functional tests, diagnostics, etc.), it is necessary to take additional appropriate safety measures (e.g. marking of the danger zone, wearing additional PPE, etc.). A full risk assessment must be conducted with the safety officer.

Precautions

Never remove the carriage from the guide rail. The 2 elements must not be disassembled. For rail replacement, the carriage is delivered pre-assembled and care must be taken that the carriage is not disassembled from the rail (e.g. by fixing temporary stops to the ends of the rail).

The guide rail must be kept clean during use. Use a soft, absorbent, lint-free cloth for cleaning.

Do not use solvents to clean the SCARA components..

Apply a light, even layer of grease to the contact surfaces, then manually move the component to its full extent and remove any excess grease with a cloth.

Regular maintenance

Clean and inspect the entire SCARA

Thoroughly clean the ballscrew and the guide rail and relubricate

Grease adapted for ballscrews (SCARA & NC): Klüber Isoflex NCA 15 grease

Grease adapted for ballscrews (SCARA & NC): Klüber Klüberplex BE 31-102 grease

Make movements by hand for each axis, check for noise, hard points, etc.

Remove any excess grease and put back into service

Replacing the SCARA Z axis drive belt

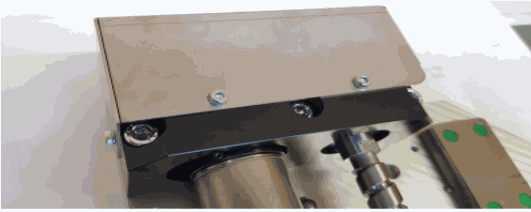

Remove the cover at the top of the SCARA assembly on the fixed part in order to access the Z transmission part.

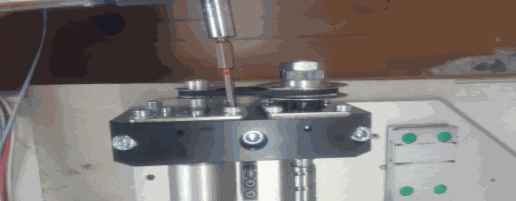

Remove the motor by undoing the flange mounting screws.

Remove the belt by passing it over the pulley flanges.

Reassembly is done by following the steps below in reverse order. The tightening torque of the motor flange mounting screws is 2.9 [Nm].

Restarting the SCARA

Replacing the B3 belt

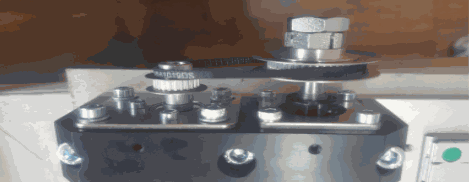

Remove the motor and cover screws and carefully remove the motor by disengaging the belt pulley and removing the plate. Remove the belt.

To reassemble, engage the belt on the disk side pulley, then offer up the motor and engage the motor pulley on the belt. Pre-tighten the motor mounting screws. Install the plate and tighten the screws to 0.22 [Nm]. Tension the belt by exerting lateral pressure on the motor towards the B2 joint. Tighten the motor mount to 0.58 [Nm].

Restarting the SCARA

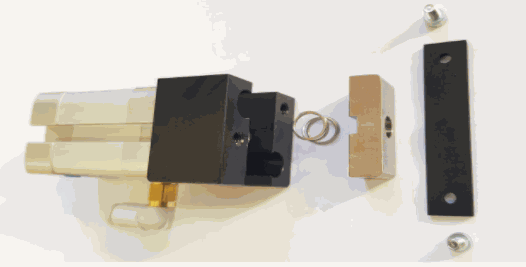

Replacement of the brake band and the Z axis spring

Remove the brake assembly from the base plate by removing the 2 mounting screws.

Unscrew the 2 screws holding the rubber plate.. Unscrew the plunger screw, replace the spring and refit the plunger. Tighten the plunger screw to 1.2 [Nm].Refit the assembly in reverse order and tighten the brake mounting screws on the base plate to 2.9 [Nm].

Restarting the SCARA

Recommissioning after intervention

Caution

Risk of collision

After any intervention on the SCARA, it is essential to perform referencing (homing): cancel the active referencing and restart complete referencing.

When recommissioning the machine after an intervention, pay particular attention to the operation of the machine.

Conduct test runs at reduced speed and keep the emergency stop button within easy reach.

There are no comments for now.