Maintenance

Completed

Regular inspection

Regular inspection

It is important to carry out periodic inspections to check the condition of the machine's various components.

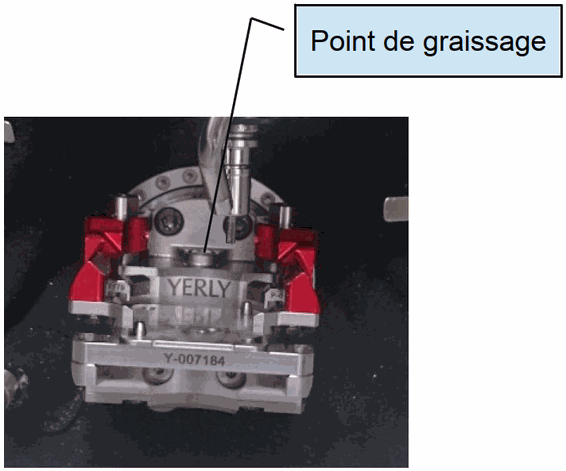

The different lubrication points are listed in the document "M353-Maintenance_21.03.19".

The type of grease and the lubrication quantity and frequency are also indicated.

CAUTION

Regularly check the condition of the protective fabric in the machining area! If it appears damaged, stop use immediately and contact MECATIS.

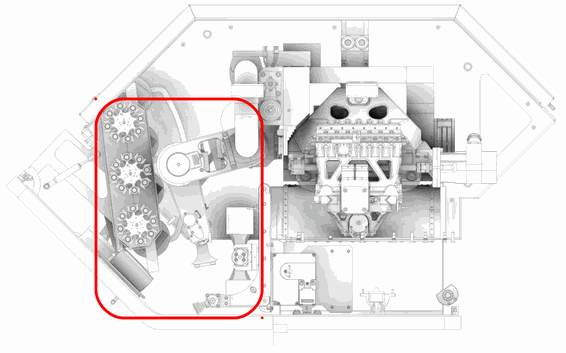

Micro5 maintenance

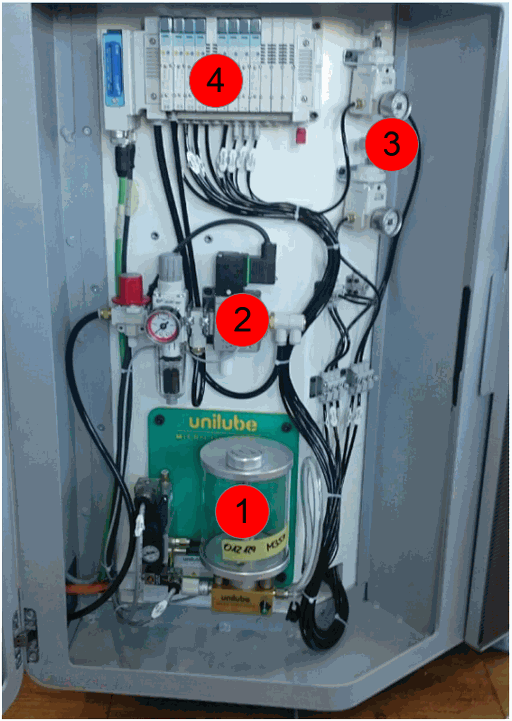

Pneumatic cabinet

1) Microlubrication

2) Air treatment

3) Spindle pressure adjustment

4) Solenoid valves

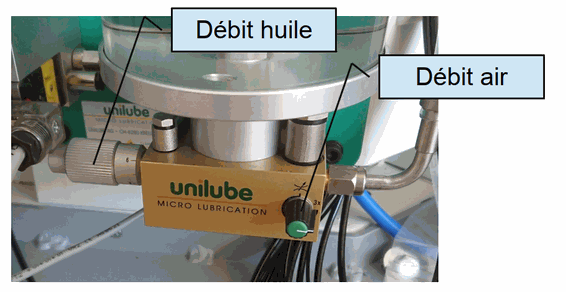

Microlubrication

Filling: max 1.5L

Unilube 9107: Gold, brass, aluminum (jewelry material)

Unilube 2032: Stainless steel, steel (relatively hard material)

Settings

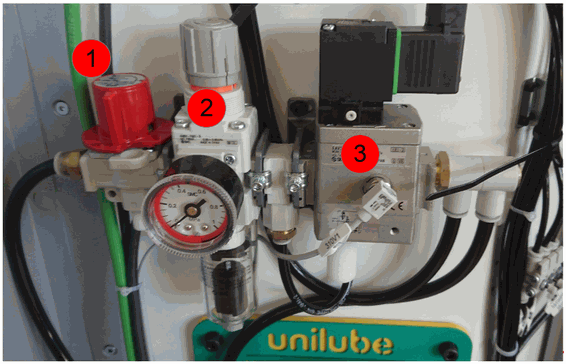

Air treatment

1) Air inlet lock

2) Pressure controller and filter

3) Discharge valve

Machine lubrication

MV rail

Supplier: Klüber

Type: Klüberplex BE 31-102 or equivalent

Brush lubrication every ~400 hours of operation depending on the condition of the rails following inspection

Ballscrew

Supplier: Klüber

Type: ISOFLEX NCA 15 or equivalent

Brush lubrication every ~400 hours of operation depending on the condition of the screws after visual inspection

Scara lubrication

Z-rail

Supplier: Klüber

Type: Klüberplex BE 31-102 or equivalent

Brush lubrication every ~400 hours of operation depending on the condition of the rail following inspection

Ballscrew

Supplier: Klüber

Type: ISOFLEX NCA 15 or equivalent

Brush lubrication every ~400 hours of operation depending on the condition of the screws after visual inspection

Top/bottom

Supplier: Klüber

Type: Microlube GBU-Y 131 or equivalent

Lubrication every 6 months of use..

Be careful not to add too much grease, as this could jam the device

Clean the machining area

1) Brush and vacuum the fabric and the area under the chip tray.

2) Remove the probe storage cover to check for chip accumulation. Clean with a brush and vacuum if necessary

3) Regularly clean the bottom guide rail of the partition

Clean the loading area

Brush and vacuum the loading area.

Beware!

Never use compressed air to blow chips into this area! There is a risk that they could settle on the screws and rails of the SCARA and the machine!

There are no comments for now.