Manual

Completed

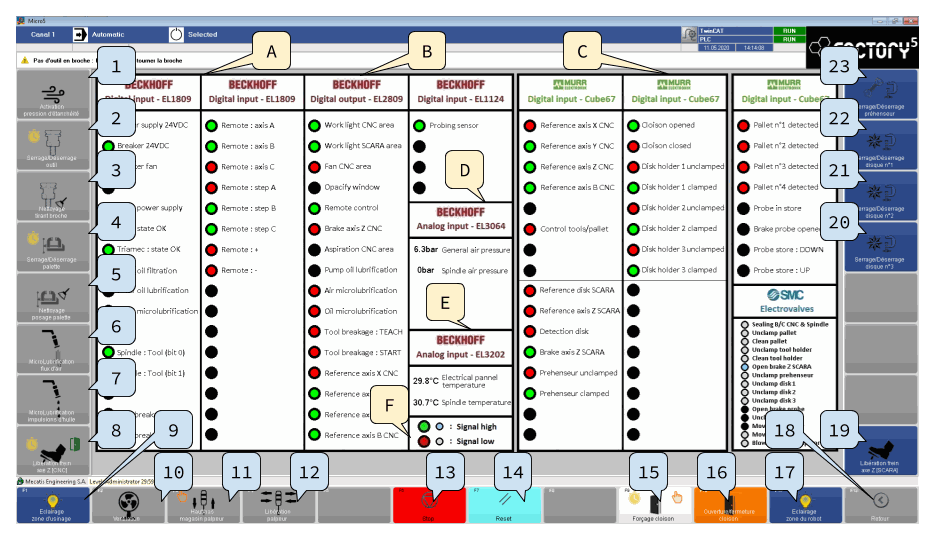

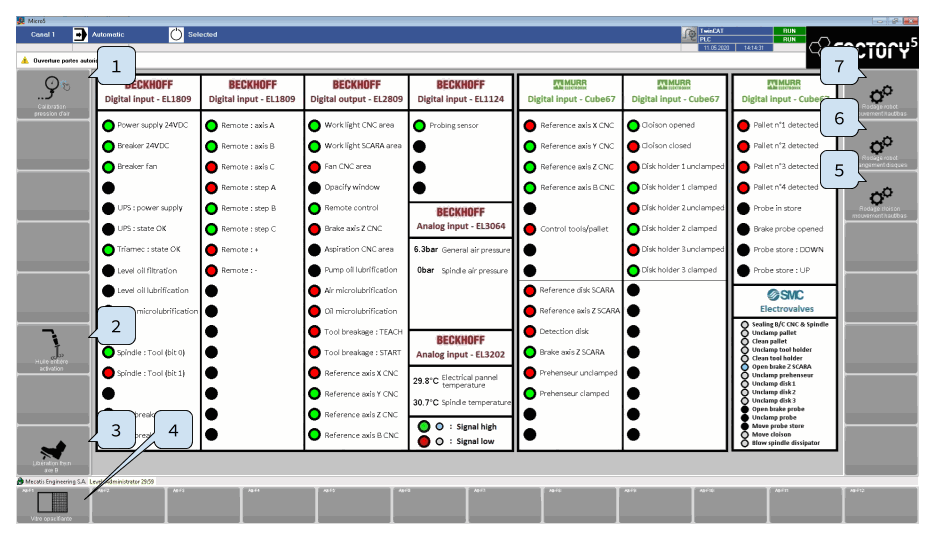

I/O State

Input/output states

This page contains all the information and functions related to the tests of the PLC inputs and outputs as well as the decentralized peripherals. The indications given on this page are the image of the signals received and transmitted by the machine. It can be useful, when searching for the cause of a failure for example, to have information directly from the PLC in order to determine the cause of the anomaly (line interruption, sensor out of order, etc.).

Active inputs/outputs are shown in green.

Inactive inputs/outputs are shown in red.

The analog values are indicated numerically, scaled and in their unit of measurement.

Zones

The screen is divided into several sections:

A) Display area for PLC digital input signals

Each column represents an input card on the PLC.

B) Display area for PLC digital output signals

Each column represents an output card on the PLC.

C) Decentralized input display area (Cube67)

Each half-column represents a remote I/O module

The pneumatic control valve island and all the control valve states are shown at the bottom right.

D) Analog input display area

This area contains the current information on the analog values measured..

E) Display area for analog temperature inputs

This area contains the current information on the measured temperature values.

F) Glossary

This area shows the representation of digital signal states..

Safety inputs/outputs

The signals for the safety functions are neither displayed nor available for manual activation. All these signals are processed by dedicated safety interfaces to ensure compliance with standards, in particular the 2006/42/EC directive.

List of main functions

Activation of sealing pressure

Tool clamping/unclamping [+T].

Spindle tie rod cleaning

Pallet clamping/unclamping [+T].

Pallet cleaning

Air flow microlubrication

Oil pulse microlubrication

Z-axis brake release CNC [+T] [+P]

Machining area lighting [F1]

Ventillation [F2]

Probe magazine up/down [F3].

Probe release [F4].

Stop [F6]

Reset [F7]

Partition forcing [F9] [+T] [+S]

Open/close partition [F10].

Robot area lighting [F11]

Back [F12]

Z axis brake release (SCARA)

Clamping/unclamping disk no. 3

Clamping/unclamping disk no. 2

Clamping/unclamping disk no. 1

List of secondary functions [+CTRL].

Air pressure calibration

Whole oil activation

B axis brake release

Switchable glass

Partition honing up/down movement

Robot honing disk change

Robot honing up/down movement

There are no comments for now.