Manual

Completed

CNC management

CNC management

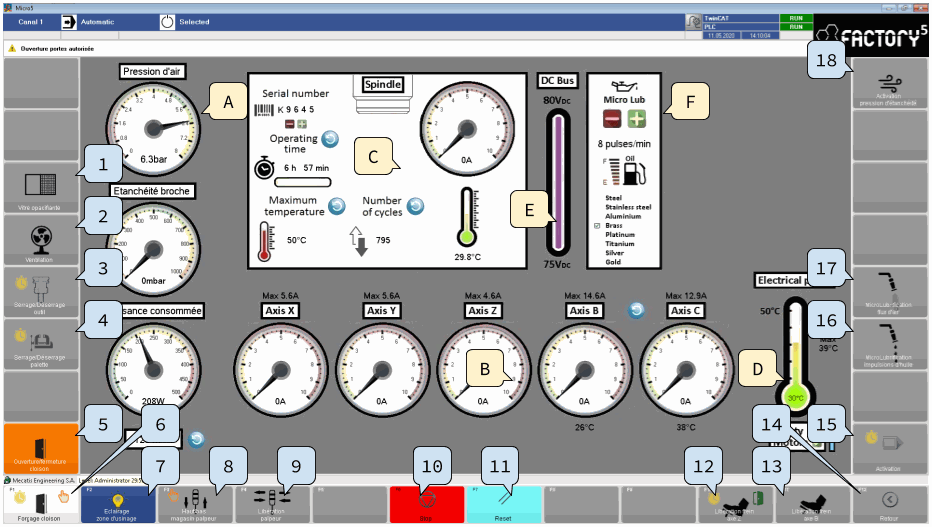

This page shows the information of the CNC part and allows the associated functions to be activated.

Zones

The screen is divided into several parts:

General air pressure: pressure measured at the machine supply

Nominal value: 6 bar (recommended: 5.5 - 6.5 bar)

Spindle sealing: pressure measured at the spindle sealing air supply

Nominal value: 550 mbar (recommended: 500-600 mbar)

Power consumption: instantaneous power consumed by the whole Micro5. The value is filtered at 1 sec.

Total consumption: the total consumption of the machine

Axis states:

Instantaneous and maximum intensity value of X, Y, Z, B and C axes

B and C axis temperature

Serial number

Hours of operation

Current and maximum temperature

Number of tool loading/unloading cycles

Current

D) Display area for the electrical part

Current and maximum temperature of the electrical part

Setting the interval of the microlubrication pulses (+0)

The lubricant level in the oil tank (+0)

Materials suitable for machining with the current lubrication setting

List of primary functions

Switchable glass [+O]: Activation of the opacification function of the glass on the machining part.

Ventilation: Activation of the ventilation on the rear part of the machining area

Activation of the spindle puller (+T): The spindle puller must be activated to allow a tool to be loaded. A tool can only be loaded if the machine is in a safe state (all axes stopped, etc.). This function requires a long press (+T)

Activation of the pallet lock (+T): Locking the pallet activates the pallet support locking system (Yerly) on the C axis. This function requires a long press (+T)

Opening/closing of partition:

Opening/closing of partition: Activates the opening of the partition between the machining and storage areas. The opening conditions must be met (doors closed, no CNC or SCARA movements, etc.)

Opening/closing of partition: Activates the opening of the partition between the machining and storage areas. The opening conditions must be met (doors closed, no CNC or SCARA movements, etc.)Partition forcing (+T)(+S) [F1]:

Activates the opening of the partition between the machining and storage areas. The opening conditions do not have to be met (closed doors, no CNC or SCARA movements...) This function requires a long press (+T). This function requires confirmation (+S)

Activates the opening of the partition between the machining and storage areas. The opening conditions do not have to be met (closed doors, no CNC or SCARA movements...) This function requires a long press (+T). This function requires confirmation (+S)Machining area lighting [F2]: Activates the machining area lighting

Probe magazine up/down [F3]: Activates downward movement of the probe magazine

Probe release [F4]:

Activates the release of the probe magazine tie rod

Activates the release of the probe magazine tie rodStop [F6]: Interruption of the current cycle

Reset [F7]: Resetting of commands and errors

Z axis brake release [F10]: Disables the Z axis brake on the CNC part.

B axis brake release [F11]: Disables the brake of the B axis on the CNC part.

Back [F12]: Link to the main page

Activation: Activation of the axes on the CNC

Oil pulse microlubrication

Air flow microlubrication

Activation of sealing pressure: Activation of the sealing pressure of the spindle and axes on the CNC

Probe magazine

When the probe is not in use, plug the female connector with the male connector attached to the cabin.

The probe must not be used for automatic loading when oil is used!

The probe magazine must not be left without a tool for a prolonged period (>10 min)

The probe is not suitable for use with oil..

Sealing pressure

The spindle and axes are supplied with compressed air to ensure positive pressure on the sensitive parts. This pressure keeps impurities (contaminants, oils, chips, dust, particles, etc.) out of the sensitive areas. For the spindle, this pressure also has an internal cooling effect on these components. It is necessary to maintain sufficient sealing pressure to avoid damage to the sensitive components of the Micro5.

Risk of pinching, crushing

The partition should only be operated manually if there are no obstacles in its path. Before initiating any movement, ensure that the doors are properly closed and that all guards are in place. If an operation requires hands to be placed into the machining area or the storage area, the energy supply must be cut off using pneumatic and/or electric disconnectors).

List of secondary functions [+CTRL].

Spindle cleaning: Activation of the spindle cone blowing function.

Pallet cleaning: Pallet cleaning: Activation of the blowing function on the C axis pallet locking system (Yerly).

Vacuum (+0): Activation of the vacuum generation function.

I/O States: Link to the PLC inputs/outputs display page

Purge microlubrication

Whole oil activation

There are no comments for now.