Manual

Completed

Tool basics

Tool basics

Sister tools

Procedure for the use of sister tools

1) When creating a main tool, define the sister tool linked to it:

click on "Add tool".

enter the number of the main tool

enter the number of the sister tool

click on "Add tool".

create a tool with the number of the brother tool

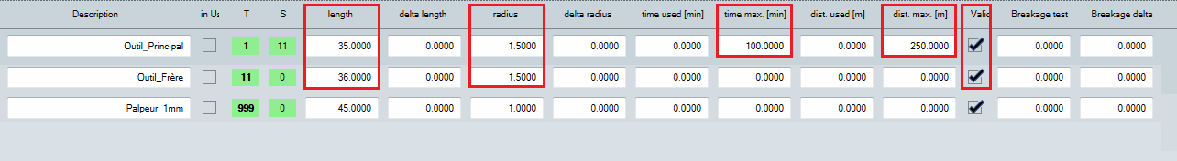

Illustration 4 : main tool

Illustration 5 : sister tool

.

2) Once the tools are created, choose the limit values for the main tool

(maximum operating time and/or maximum operating distance)

A) Time and distance are only incremented with working feeds [G1].

B) If both maximum values are zero, the sister tool will not be loaded:

enter the length and radius values of the two tools

enter the values for maximum operating time and/or maximum operating distance for the main tool

check the validation of both tools

3) If one of the two limit values is exceeded, the sister tool is loaded into the spindle when the main tool is called.

A) On the main page, the sister tool "Tx" and its correction "Dx" will be displayed in the "Technical Data".

Remarks

it is not possible to link several sister tools to the main tool

It is not possible to sequence the tools

ex : T1 → T11 → T21 → T31 → …

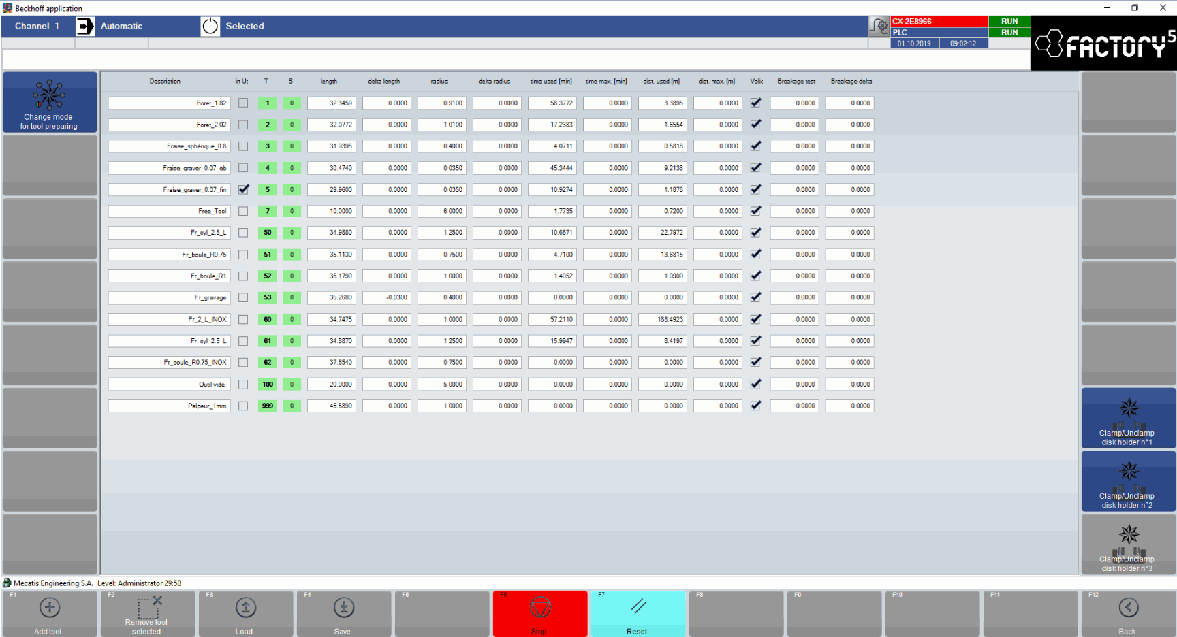

Tool management list

| Description: Tool name | Time max: Time limit before deactivation of the tool and switching to a sister tool |

| In Use: Checked if tool is active in the spindle | Time used: Total time |

| T : Tool number | Distance used: Total distance |

| S: Sister tool number | Max distance: Operating distance limit before deactivating the tool and switching to a sister tool |

| Length: Tool length (from reference face ATC15) | Valid: Checked if tool valid for use |

| Data Length: Tool length adjustment | Tool breakage: Enter 1 to activate the tool breakage test during the tool change |

| Radius: Tool radius (for G41/42 correction) | Delta measurement length: offset in mm from the tool tip for contact during the tool breakage test |

| Delta radius: Tool radius adjustment |

There are no comments for now.