Manual

Completed

Initial conditions

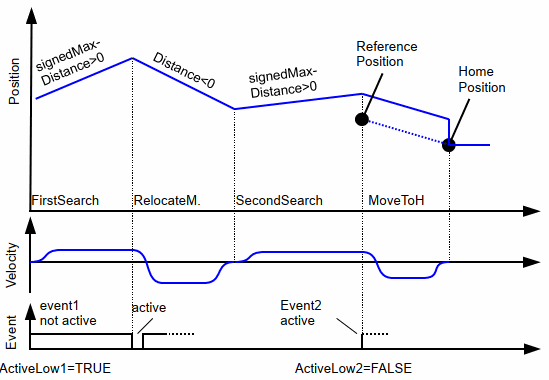

Initialization of the axes

All the axes of the Micro5 are equipped with incremental movement measuring systems (encoders), therefore all the machine axes must first approach a reference point (index) whose coordinates in relation to the machine origin are known. Initialization is a fully automatic sequence performed at low speed.

Initialization sequence (simplified)

The axis moves slowly in the positive direction

If the index is found 3

If the index is not found 2

The axis moves slowly in the negative direction

The index is found = the axis is initialized

The axis moves to the disengaged position

After initialization of all axes, return to the initial position.

This initialization must be carried out when the system starts up and for both parts of the Micro5:

CNC

SCARA

Referencing of the CNC part axes

Prerequisites:

There must be no faults on the machine (emergency stop engaged, anomalies, etc.)

The axes must be in their nominal position (in their working area, outside the limits)

The doors must be closed

The Scara must be located in the storage area

The partition must be closed

No tool in the spindle

No pallets in the machining area

Procedure:

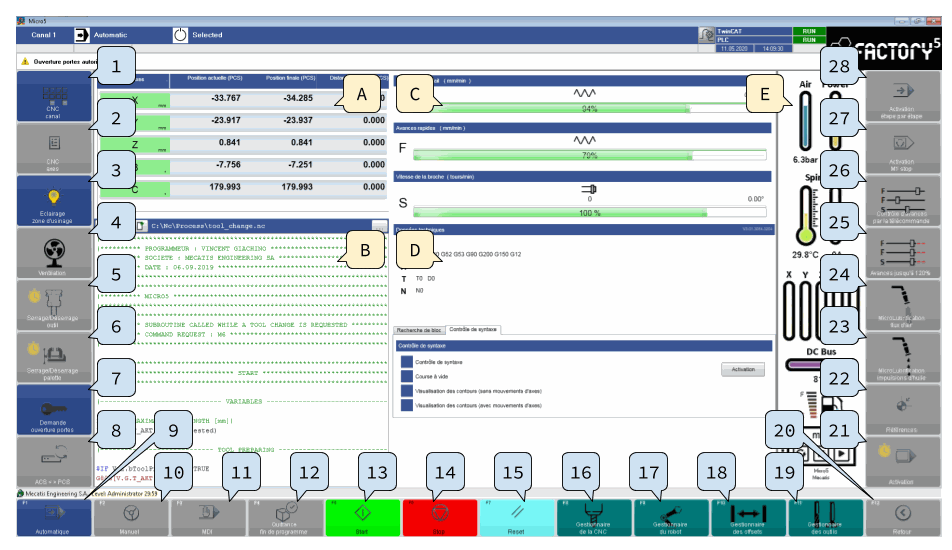

On the main page, activate the axes (21)

Activate referencing (22)

The axes will move in turn to find their index

Once their index is found, their coordinates are set to zero

Each axis moves to its initial position.

The interface displays the tool in the spindle

(I)

(I)

If the axes are correctly referenced, they appear in green in zone A

If an error has occurred, they appear in red and an error message is issued

Risk of collision

The reference cycle is a process in which the axes of the CNC part are automatically activated.

The axis positions cannot be reliably determined until referencing is completely and correctly executed. Due to the path, speed and movements of the axes, a collision cannot be ruled out if a tool or workpiece is installed.

Before referencing:

Remove the tool from the spindle

Remove the pallet

(II) Verification of data consistency

Always check that the tool number and pallet number physically present on the Micro5 correspond to those displayed on the interface.

There are two possible scenarios depending on the version of the Micro5 software:

Software versions before 25.06.2020, 13:38 -->||

The tool in the spindle when the machine is switched off is lost; the tool number must be entered manually when switching on.

In MDI mode, enter the tool number in the program entry section and start.

|-->Software versions from and including 25.06.2020, 13:38

The tool in the spindle when the machine is switched off is stored. When the Micro5 is switched on, the tool stored when the machine is switched off is automatically transferred to the interface when the reference is taken. Tools should therefore not be manually changed before a homing operation has been performed.

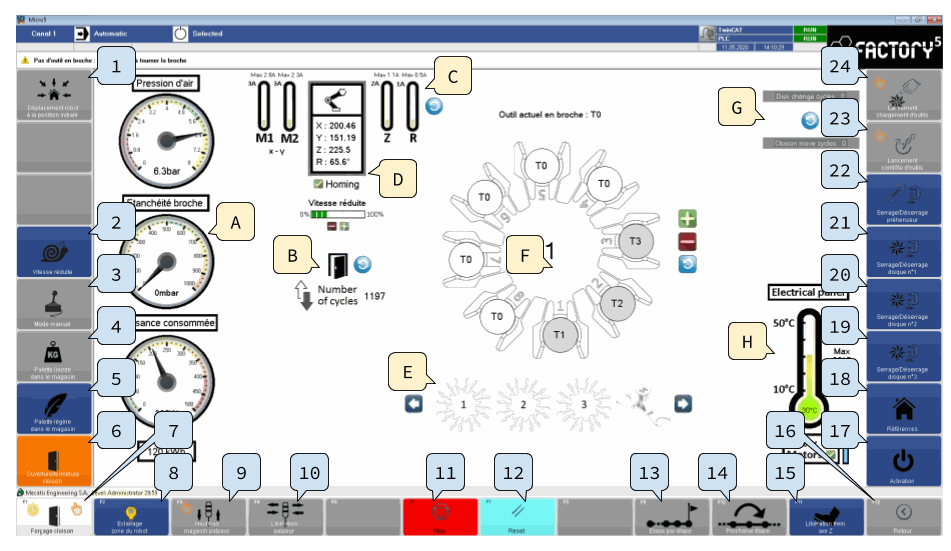

Referencing the SCARA part axes

Referencing of the SCARA is called "Homing". the procedure is similar to that of the NC part. It is not possible to perform any movement in manual or automatic mode until the SCARA has successfully completed the Homing procedure.

Prerequisites:

There must be no faults on the machine (emergency stop engaged, anomalies, etc.)

The doors must be closed.

the SCARA must be in the storage area

Partition closed.

SCARA in safe position

(II)

(II)  (I) (approximativelyt).

(I) (approximativelyt).Check that the accessory mounted on the SCARA is the same as the one shown on the SCARA management page

(II).

(II).The gripper must not be loaded on the SCARA

Surfaces must be cleaned

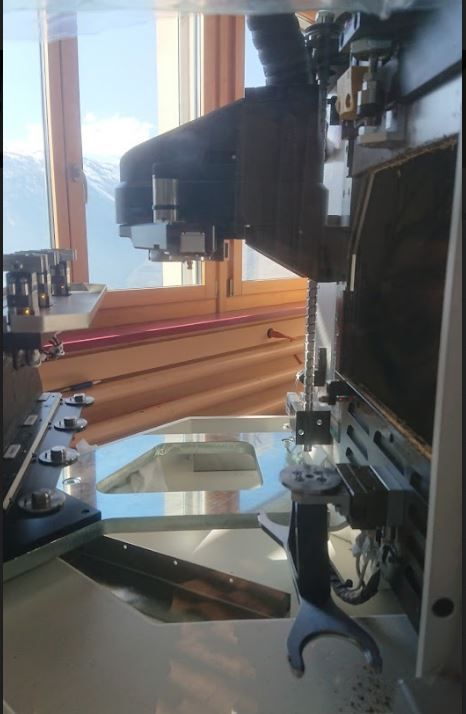

(I) Safe position of the SCARA (pre-homing)

The safe position of the SCARA is shown in the photo:

- Z: Intermediate height (>50 mm from stops)

- B1: "Arm" facing rearwards

- B2: "Forearm" facing forwards

- B3: disk rotation any position

Procedure:

On the SCARA management page, activate the SCARA axes (17)

Activate referencing (18)

I) Risk of collision

The SCARA must be manually moved to its safe position before homing. After a SCARA deactivation, if the SCARA has been moved manually, it must be moved back to its safe position and homing performed.

II) Risk of collision

Always make sure that the handling accessory present in the SCARA is correctly entered in field E "Indication of loaded accessory".

After a reset, a restart or an emergency stop, it is possible that the Micro5 has not correctly stored the accessory loaded on the SCARA. Movement with an attachment can result in collisions and damage to the machine.

Never reference with the pallet gripper mounted on the SCARA. If necessary, the SCARA paddle gripper must be removed manually.

It is not recommended to perform referencing with a disk mounted on the SCARA. It is possible starting from the initial position. However, from any other position there is a risk of collision.

Movements performed by hand

If for some reason it is not possible to activate the SCARA or it is preferable to manually position the SCARA, it is possible to move the arm of the SCARA carefully by hand in order to position it correctly for homing. To perform this operation, the SCARA must not be activated and the Z axis brake (15) must be released.

Moving the SCARA by hand

If the SCARA needs to be moved by hand, ensure that:

The SCARA is deactivated

The SCARA Z-brake is deactivated

To avoid changing the alignment of the SCARA's Z axis guide, it is imperative to perform the movements by hand with care, limiting the torsional forces and holding the SCARA's arm as close as possible to the Z axis guide carriage.

There are no comments for now.