Manual

Completed

Main page

Main page

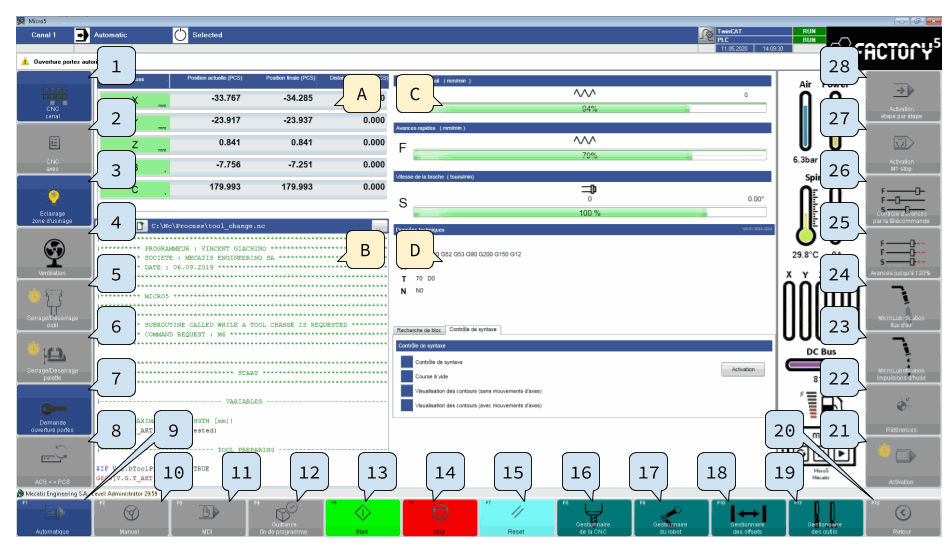

This page contains all the information and functions that are useful during machining. A light version is available (go back to the home screen and press [CTRL] then click on "Micro5 [F4]".

Zones

The screen is divided into several parts:

A) Axis coordinates display area

The axes are green if they are operational and referenced, in red if they are faulty.

Their current position, target position and remaining distance are shown based on the selected coordinate system (V/Function 8)

B) Program display area

The display in this area depends on the machine's operating mode:

- If the machine is in automatic mode: the program being run is displayed

- If the machine is in manual mode: the control options are displayed

- If the machine is in "MDI" mode: the code editor is displayed

C) Feeds display area

The working feed and rapid feed speeds F are displayed, as well as the spindle speed S in text form in % and graphically.

An indication of the axis load is displayed above these indications

D) Mode display zone

This zone contains the current information on the active codes (the tool currently in the spindle, active function, etc.)

E) Machine information display zone

This zone contains the machine's summarized load and condition indicators.

The CNC management page contains detailed information.

List of primary functions

CNC Channel

Activation of the standard display: The standard display excludes the coordinates of the spindle axis, as this information is relatively useful.CNC Axes

Activation of the detailed display (all axes): The detailed display includes the spindle coordinates but reduces the area reserved for the program display.Machining area lighting

Activation of the machining area lightingVentilation

Activation of the rear zone suction (cooling)Tool clamping/unclamping (+T)

Activation of the spindle puller (+T): The spindle puller must be activated to allow a tool to be loaded. A tool can only be loaded if the machine is in a safe state (all axes stopped, etc.). This function requires a long press (+T)Pallet clamping/unclamping (+T)

Activation of the pallet lock (+T): Locking the pallet activates the pallet support locking system (Yerly) on the C axis. This function requires a long press (+T)Request for door opening

The door remains locked by default, even at the end of a cycle or after a reset. Activating the door opener unlocks the door after 2 seconds of inactivity.ACS/PSC [F1]

Activation of the ACS and PCS reverse display: This function allows you to switch between the two coordinate systems: ACS (Axis Coordinate System) and PCS (Part Program Coordinate System)Automatic [F1]

Activation of the automatic operating mode: This operating mode allows the CNC to be used to execute complete machining programsManual [F2]

Activation of manual operating mode: This operating mode allows the CNC to be used with the remote control to make manual movements manuellementMDI [F3]

Activation of code block operating mode: This mode allows you to execute an isolated block of code by entering directly into the program display area.End of cycle validation [F4].

Start [F5]

Cycle start: starts the cycle (machining program)Cycle interruption [F6]

Reset [F7]

Reset: Resets the CNC to its initial mode and deletes the current non-active faultsReturn [F12]

Link back to the home pageActivation (+T)

Activation of the CNC part: Activates the power supply for the axis controllers (Drives) of the CNC part.References

Activation of the reference cycle for the CNC partMicrolubrication oil pulses (+O)

Activation of microlubrication (+O)Air flow microlubrication (+O)

Activation of blowing during machiningFeeds up to 120 %.

Activation of rapid feeds x1.2Remote feed control

Remote control activation of the feed speed controlActivation M1 Stop

Activation of M1 breaks in the machining programStep-by-step activation

Activation of the step-by-step program execution mode

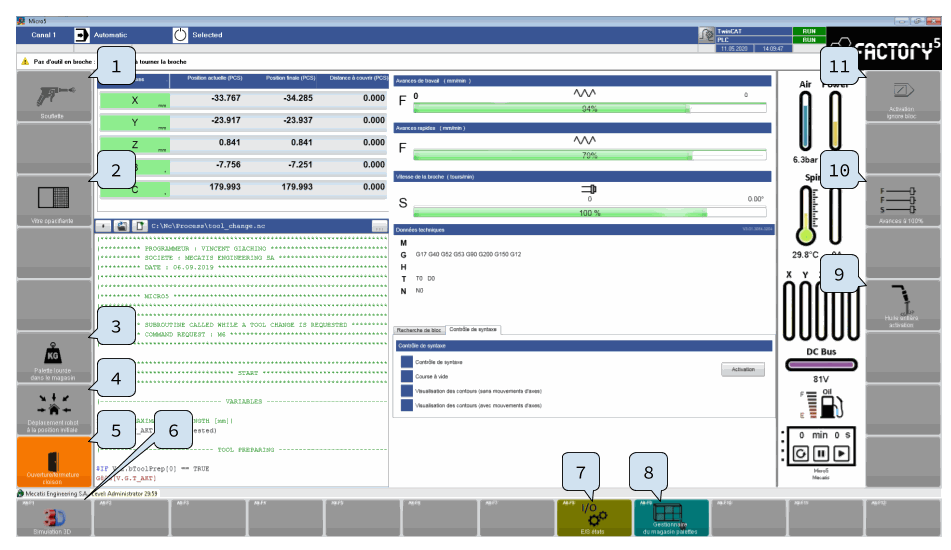

List of secondary functions [+CTRL].

Blower

Activation of the compressed air outlet on the front panel.Switchable glass (+O)

Activate the opacity function of the machining part door. This function is available if the corresponding option is present on the machine.Heavy pallet

Activation of the SCARA handling parameters adapted to heavier pallets. Speeds and accelerations are adjusted accordingly.Move to home position

Activation of the SCARA return to home position cycleOpening/closing partition

3D Simulation [Alt+F1]

E/S States [Alt+F8]

Link to the PLC inputs/outputs display pagePallet management [Alt+F9]

Link to the pallet management pageWhole oil activation

Feeds at 100%.

Resets the feed rate setpoints to 100%.Activation ignores block

Risk of damage to the spindle tie rod

In order to protect the cone from contamination and to avoid sr-deformation of the socket, before switching off the machine or during a prolonged stoppage (>2 hrs), it is necessary to fit a tool in the spindle and release the tie rod (locked position)."

There are no comments for now.